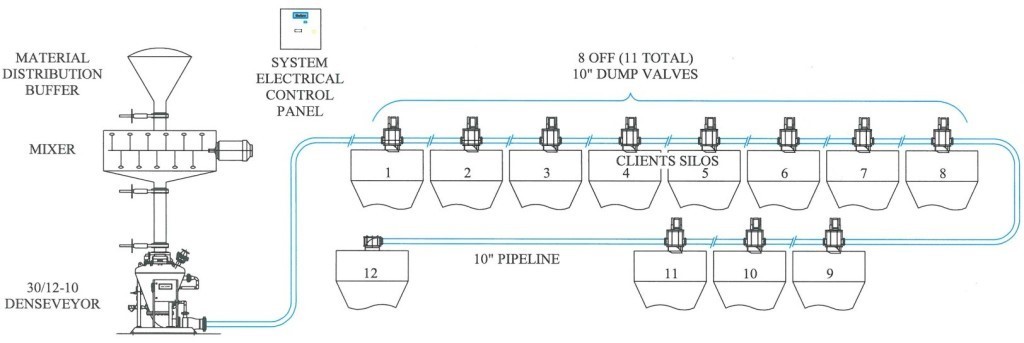

Case Study: Mixed Mortar Conveying Systems, Holland

The low velocity dense-phase pneumatic conveying system supplied conveys in 90t/h of mixed mortar over a distance of 109.728 m horizontal and 35.052 m vertical. The system uses a 1.47248 cubic meter vessel with a 203.2 mm pipe line. The system is located under a mixer which in turn is fed by multiple product feed hoppers. The starting and stopping sequence of the system is controlled automatically from a central control room via an internet connection. The pneumatic conveyors are working very reliably and exceed the customer’s expectations regarding rate transferring over 130t/h. The system incorporated multiple manifold settings allowing the transfer of a wide range of bulk materials and sizes. The system set-up is done automatically simply by selecting the material recipe. Further options have been added since the initial start-up including a four way diverter valve and the addition of more reception silos and conveying lines. The end user is extremely satisfied with the system and the flexibility it offers considering the hundreds of different mixes that need to be conveyed.

MATERIAL CHARACTERISTICS

| Mixed mortars | 0.127 mm to 12.7 mm |

| Bulk Density | 64 – 120 lb/ft³ |

| Temperature | 60°C |

| Moisture Content | 0% |

| Condition | Free Flowing with aeration |

SYSTEM OBJECTIVES

- Dense-phase low velocity conveying and low wear

- Reliable operation

- Flexibility to allow multiple product mixes

SYSTEM PERFORMANCE

| Transfer Capacity | 90t/h (actual up to 130t/h) |

| Conveying Distance | 144.78 m |

| Reception Points | 1 feed and 11 reception points |

IMPROVEMENTS ACHIEVED

- Increased transfer rate

- Reduced compressed air requirements

- No mixing or product between material changes

For more information contact us at Mactenn (a sister company of Macawber Engineering Inc. in the U.S.)