System loaded on transport vehicle

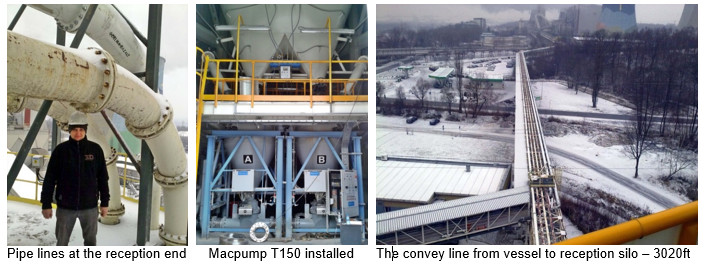

The Mactenn (a sister company of Macawber Engineering Inc. in the U.S.) Macpump T150, a single system, but with two vessels. As one is conveying, the other is filling and preparing to convey. The pneumatic conveying distance is 900.68 m horizontal and 19.81 m vertical conveying over 100t/h of crushed limestone. The convey line starts at 304.8 mm and finishes at 355.6 mm. This was a challenging application due mainly to the limestone material being out of specification relative to the initial sample upon which the system was designed. However, with a few small modifications and careful optimizing the system achieved all the customer’s specifications and is now working 24 hours per day 7 days a week at a power station. Batch size and sequence control is by two sets of load cells with system control selectable either from the central control room via Ethernet communication protocols or at the local panel.

MATERIAL CHARACTERISTICS

| Crushed Limestone |

0.02032 mm to 1.016 mm |

| Bulk Density |

69 lb/ft³ |

| Temperature |

40°C |

| Moisture Content |

1.0% Maximum |

| Condition |

Free Flowing |

SYSTEM OBJECTIVES

- Dense phase low velocity conveying.

- High transfer rates.

- Reliable operation.

SYSTEM PERFORMANCE

| Transfer Capacity |

Over 100t/h |

| Conveying Distance |

920.496 m |

| Reception Points |

2 |

IMPROVEMENTS ACHIEVED

- Increased transfer rate.

- Reliable operation.

- Low degradation.